Product Description

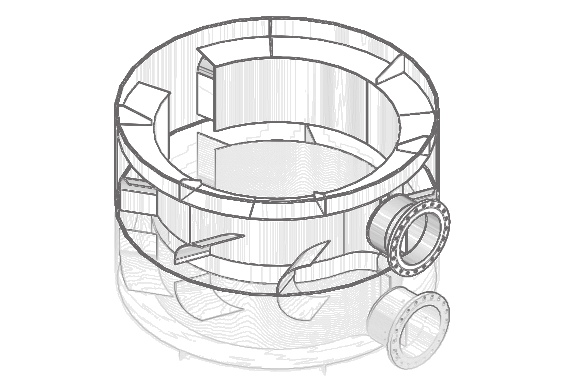

Vapor inlet distributor

The uniform distribution at the inlet of feed gas has significant impact on the separation efficiency and product quality of large distillation columns.This is because the resistance drop of packings is generally small in large towers. Thus making it difficult for the gas to self-correct its distribution pattern.

The height/diameter ratio of packed bed is small in large towers. However, the gas inlet velocity is extremely high. Without a suitable gas distributor:

⑴ Gas deviation greatly reduces the separation effect of the packing.

⑵Residue droplets are entrained in the updraft gas stream, which reduces the quality sideline products.

⑶The uneven distribution of gas leads to high local gas velocity, resulting in dry plates, coking, and blockage.

Therefore, the design of a gas-liquid feed distributor is quite important for large packing towers.

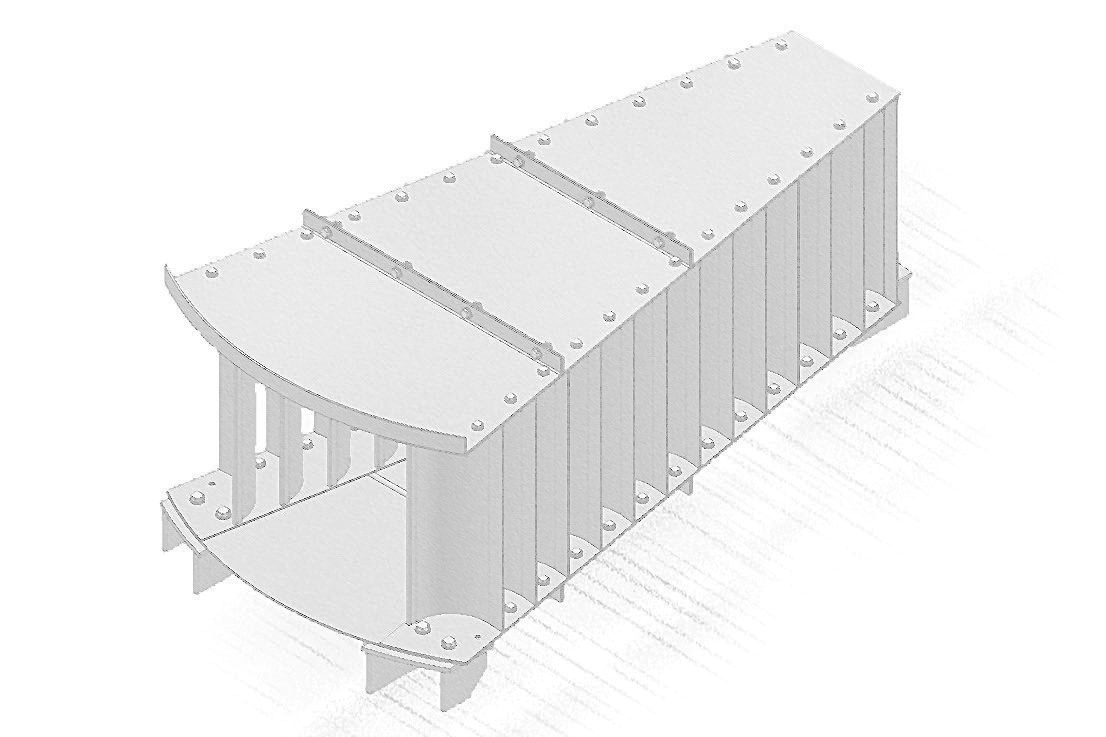

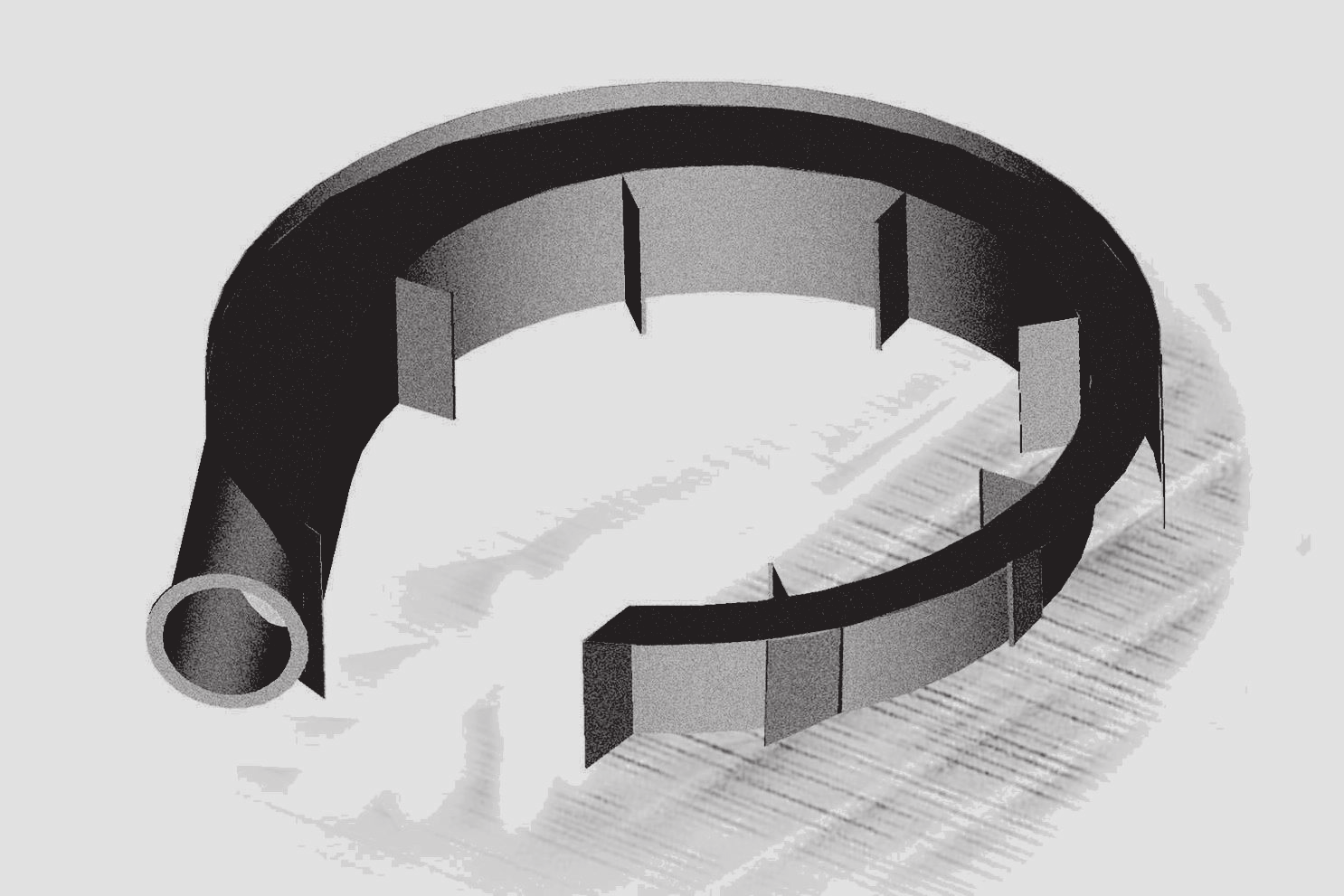

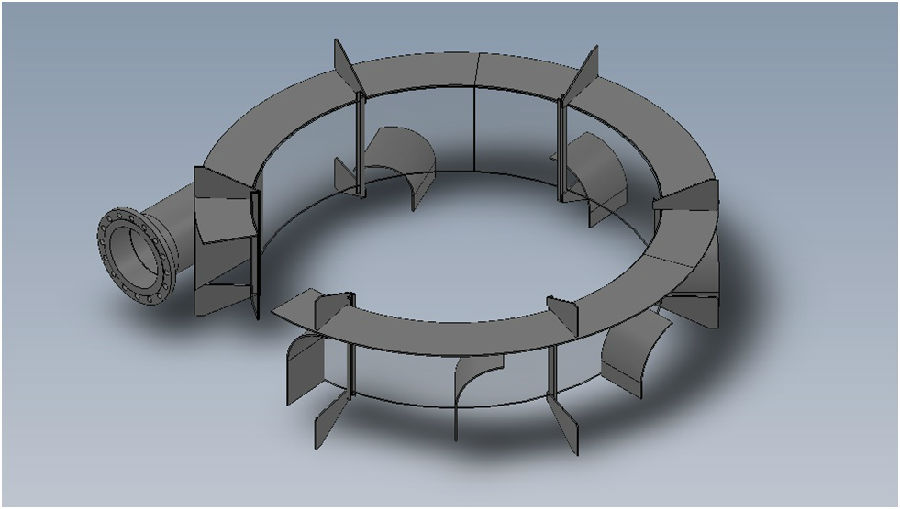

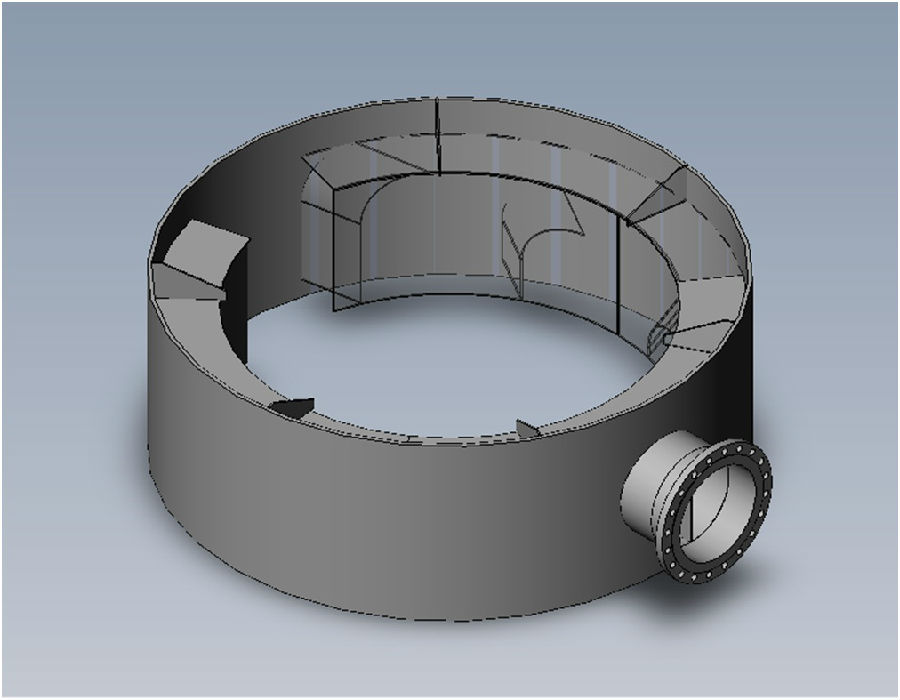

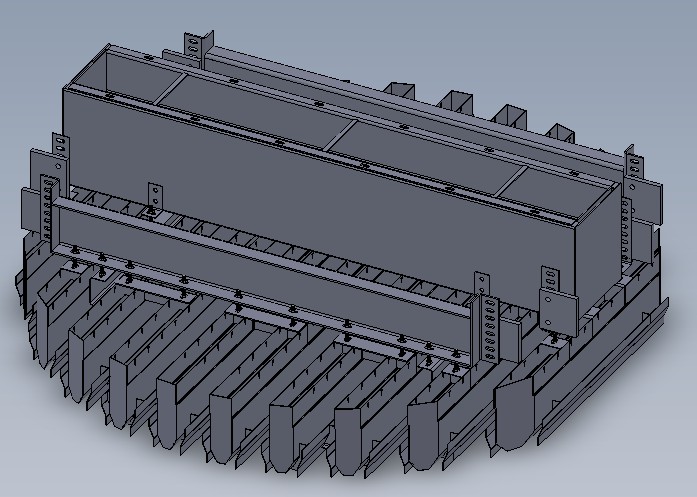

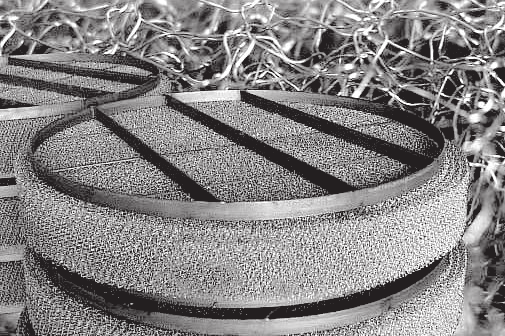

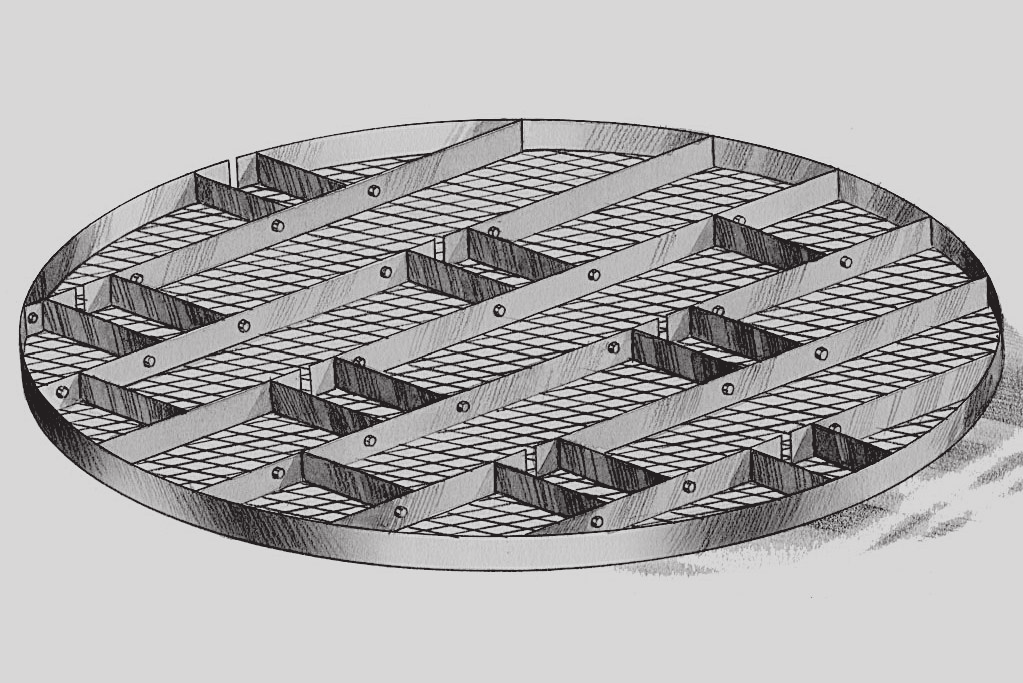

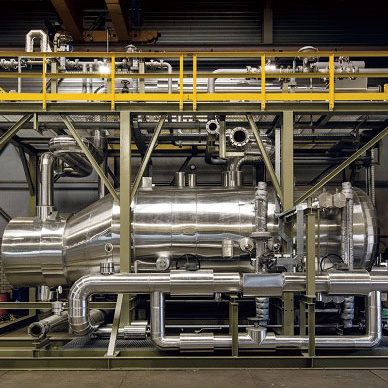

As shown in the figure, the structure of the distributor ensures the cross section of the mixing channel is gradually expanded. In this case, the energy loss is low and the airflow resistance is small.

The air flow pattern (from horizontal radial flow to downward then upward) allows the liquid to be effectively separated and the entrainment is reduced. The uniformed gas distribution allows low entrainment rate (less than 1/1000) and low pressure drop (less than 2mm water column).