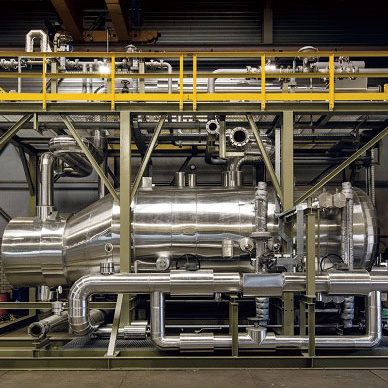

In addition to the development of high-efficiency tower trays, Xiesheng also provides a series of customizable conventional trays that meet the needs of clients. No matter what type of tower trays our clients need, our experience in professional engineering design ensures that we can always provide the best solution.

Conventional tower tray

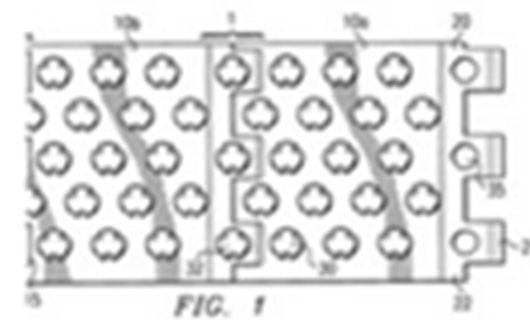

Floating valve tray

A floating valve is the component that ensures efficient gas-liquid contact. It has several spherical openings on the tray plate, and each opening is equipped with a valve that can float up and down. The main types of floating valves are F-1 (most commonly used), V-4, A and cross.

The F-1 type floating valve has two configurations, light and heavy. The former has a thickness of 1.5 mm and weighs 25 g. It has smaller inertia, higher vibration frequency, longer closing time lag, and higher liquid leakage at low gas velocity. It is recommended to be used in large capacity and...

Bubble cap tray

The bubble cap tray has the advantages of large operation flexibility, large production capacity, resistance to plugging, easy to operate, stable, and reliable. It is suitable for cases of low liquid load and high operation flexibility requirement.

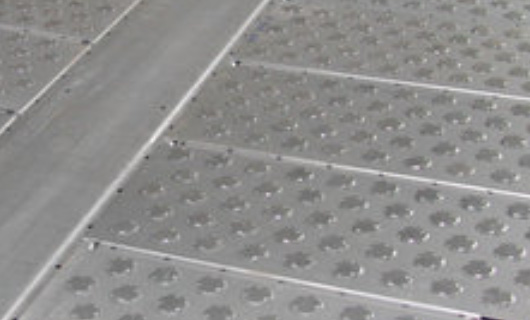

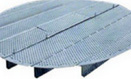

Sieve tray

The sieve tray is one of the earliest forms of tower trays, it can be used as a low-cost solution when high operational flexibility is not required. We can provide design for all existing conventional sieve tray trays, including small openings for increased steam capacity and venturi holes for low pressure drop.

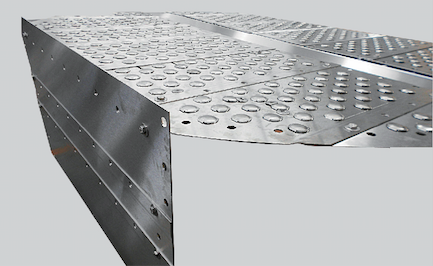

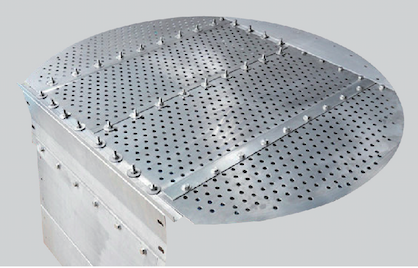

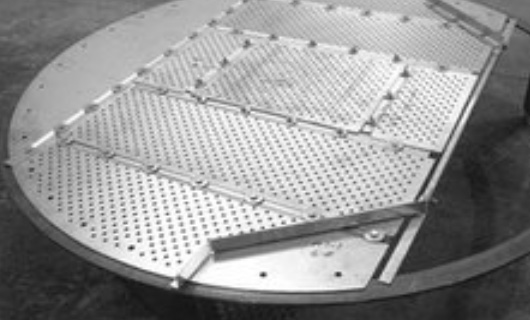

Cartridge tray

The cartridge tray is usually used in some small towers that have no manhole. These towers usually have diameter between 300 ~ 800 mm (12”~30”). Integral trays are generally assembled in a series manner for easier and faster installation. The trays can be equipped with various types of tray plates and downcomers...