The primary function of the liquid collector is to collect and redistribute liquid and gas inside the tower. Our company mainly consider the following factors when designing liquid collectors : ⑴Shortening liquid residence time of liquid to prevent local retention. ⑵Promote uniform distribution of gas and reduce gas resistance.⑶Structural design : high strength, resistance to thermal expansion and contraction ⑷Small amount of onsite welding...

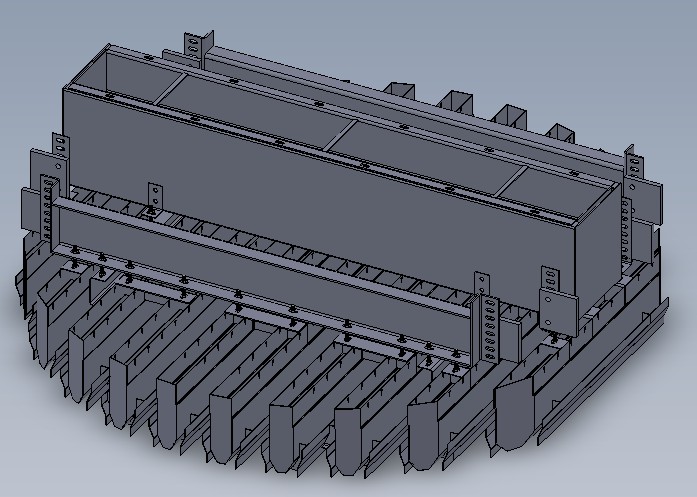

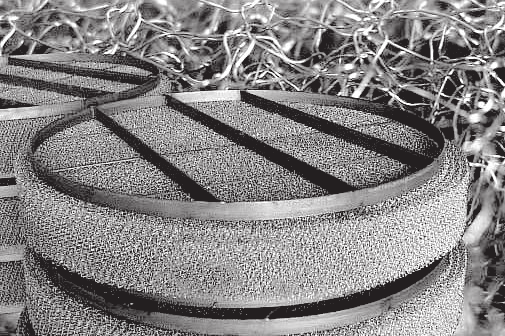

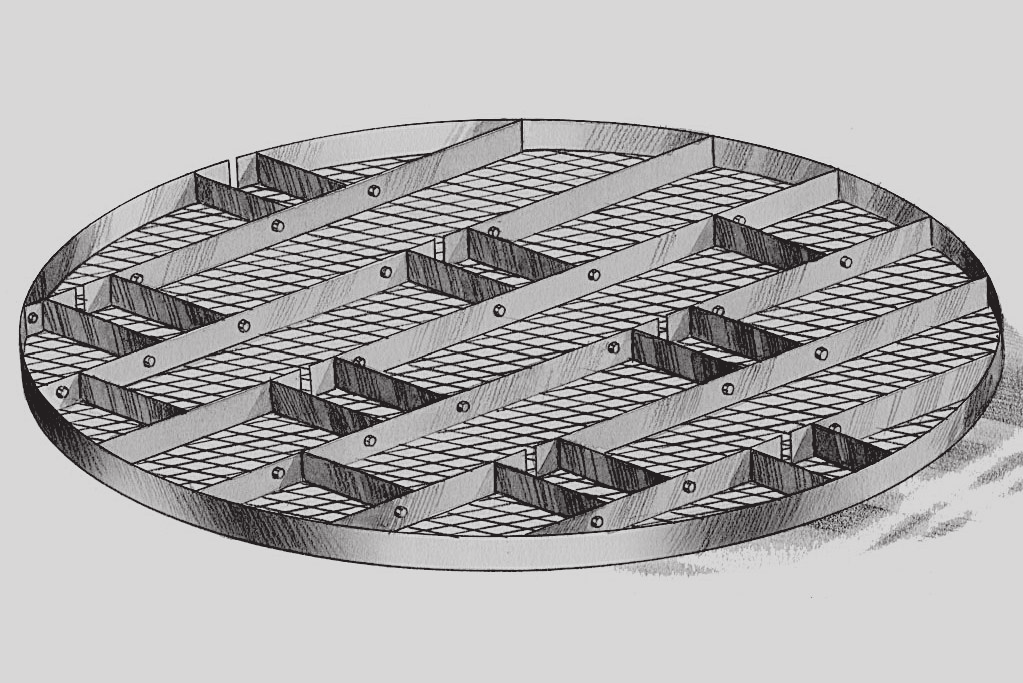

Liquid collector

The primary function of the liquid collector is to collect and redistribute liquid and gas inside the tower. Our company mainly consider the following factors when designing liquid collectors :

⑴Shortening liquid residence time of liquid to prevent local retention.

⑵Promote uniform distribution of gas and reduce gas resistance.

⑶Structural design : high strength, resistance to thermal expansion and contraction

⑷ Small amount of onsite welding

According to the design philosophy above, our company’s liquid collector generally designed in following manner:

⑴Strip-shaped riser is used, which has relatively large opening rate, small gas resistance, and it is easy to be installed on the field.

⑵The design of main pan is focused on reducing liquid residence time.

⑶The support groove tilts to the center, which promotes liquid flow and eliminates the liquid retention.

⑷The structure is resistant to gas impact and thermal expansion and contraction.